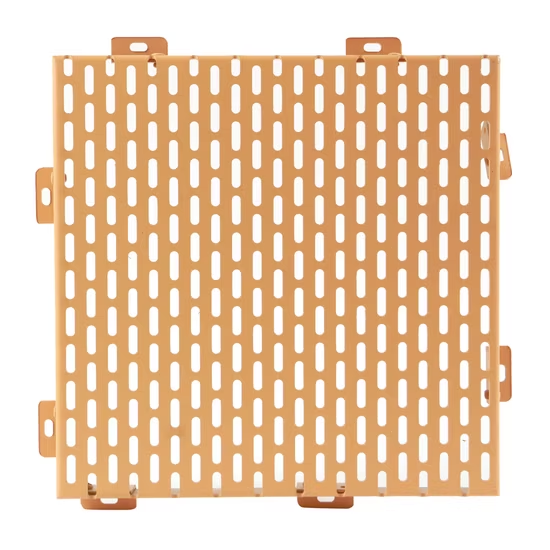

Laser Cutting Metal Wall Cladding Aluminum Solid Panel Decorative Building Facades Aluminum Plate Panel

Basic Info.

| Model NO. | aluminum 3003 |

| Metal Curtain Wall Kind | Aluminum Panel Curtain Wall |

| Shape | Flat/Perforated/Carved/Hyperboloidal/Customized |

| Usage | Exterior Wall, Interior Wall, Interior,Outdoor Wall Cladding Decoration |

| Specila Function | Ventilation Curtain Wall |

| Transport Package | Protective Film+Tray+Plywood |

| Specification | custom size |

| Trademark | PRINCETON |

| Origin | Linqu Shandong China |

| HS Code | 76109000 |

| Production Capacity | 10000pieces/Month |

Product Description

Product Description

All our aluminum laser cutting screens are of the highest quality and designed to resist corrosion throughout all seasons. This screen is robust, yet lightweight . The surface is powder coatting color, ensuring that it will stand the test of time in both commercial and residential settings.| item | details |

| Aluminum alloy | 3003,5052,1100 |

| Panel thickness | 2.0mm,2.5mm 3mm,3.5mm,5mm/customized |

| Surface | powder coating/wood grain/other |

| Shape | Flat/Perforated/Carved/Hyperboloidal/Customized |

| Usage | Interior,Outdoor Decoration |

| Place | Building,Hotel,Office,Room,Garden. etc |

Detailed Photos

1. We are factory, customized patterns are welcomed. If you don't like our standard pattern.Pls contact our product manager and send your own pattern. We can help you make it ture.2. All of our laser cutting plate will be polished. The surface has been polished without burrns .The polished surface increases the adhesive force of the powder.3. All our aluminum products are pretreated before powder coating .Therefore we can offer you 10 years warranty. After 10 years ,it may fade slowly but will never lose powder and rust for lifelong .PRINCETON METAL specialize in custom sheet metal fabrication for different kinds of materials with high precision laser cutting, CNC punching, stamping, bending, machining, welding, powder coating and assembly service. As a factory with 6000 square meter workshop and 110 workers , we are able to save cost of labor and shorten production lead time, which enables us to compete with others. "First class quality with competitive price is the source of business." is our motto

Our Advantages

1.Colorful, durable, non-fading,2.Environmental protection, fire prevention, moisture proof,3. Variety, pattern, color can be customized according to user requirements.4.Good flatness, moisture resistance and oil resistance5.Excellent corrosion resistance, resistance to moisture, UV6. Impeccable fireproof, moisture-proof and corrosion-resistant functions, sound absorption, good thermal insulation performance, perfect sound absorption7.The aluminum mesh plate has a compact structure and seamless stitching, which can maintain no discoloration for 10 years;8. Non-toxic, tasteless, environmentally friendly, 100% recyclable

more product

Aluminum wall panels are processed from high-quality aluminum plates. With PVDF coating on the surface, the panels are protected from UV, temperature, humidity, and atmospheric erosion. Aluminum wall panels perform excellently at anti-bending and anti-wind pressure, which makes it conducive to working and secondary development.The aluminum wall panels have many advantages, such as light specific weight, high strength, waterproof, anti-fouling, fire prevention, corrosion prevention, good processing performance, low maintenance cost, and a long service life.Aluminum wall panels can be processed into a variety of arcs and contours, and the surface can be sprayed into varying colors, forming all sorts of beautiful patterns on the wall. The combinations of aluminum wall panels and glass curtain wall or other materials make the building become more noble and elegant.The ideal aluminum laser cutting screen is to hide an unsightly neighbor's backyard, block unwanted direct sunlight, create privacy, or frame an outdoor room. Add elegance, beauty and value to your home with low maintenance aluminum laser cutting products.

Packaging & Shipping

1. Every piece was packed with thermal shrinkage film or plastic bag or carton board.2. Stacked together on the steel pallet and bined with packing tape.3. The whole pallet was wrapped with plywood .4.The pallets were wrapped with film again.